Mooring Systems

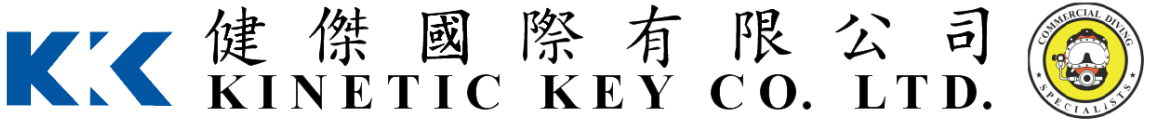

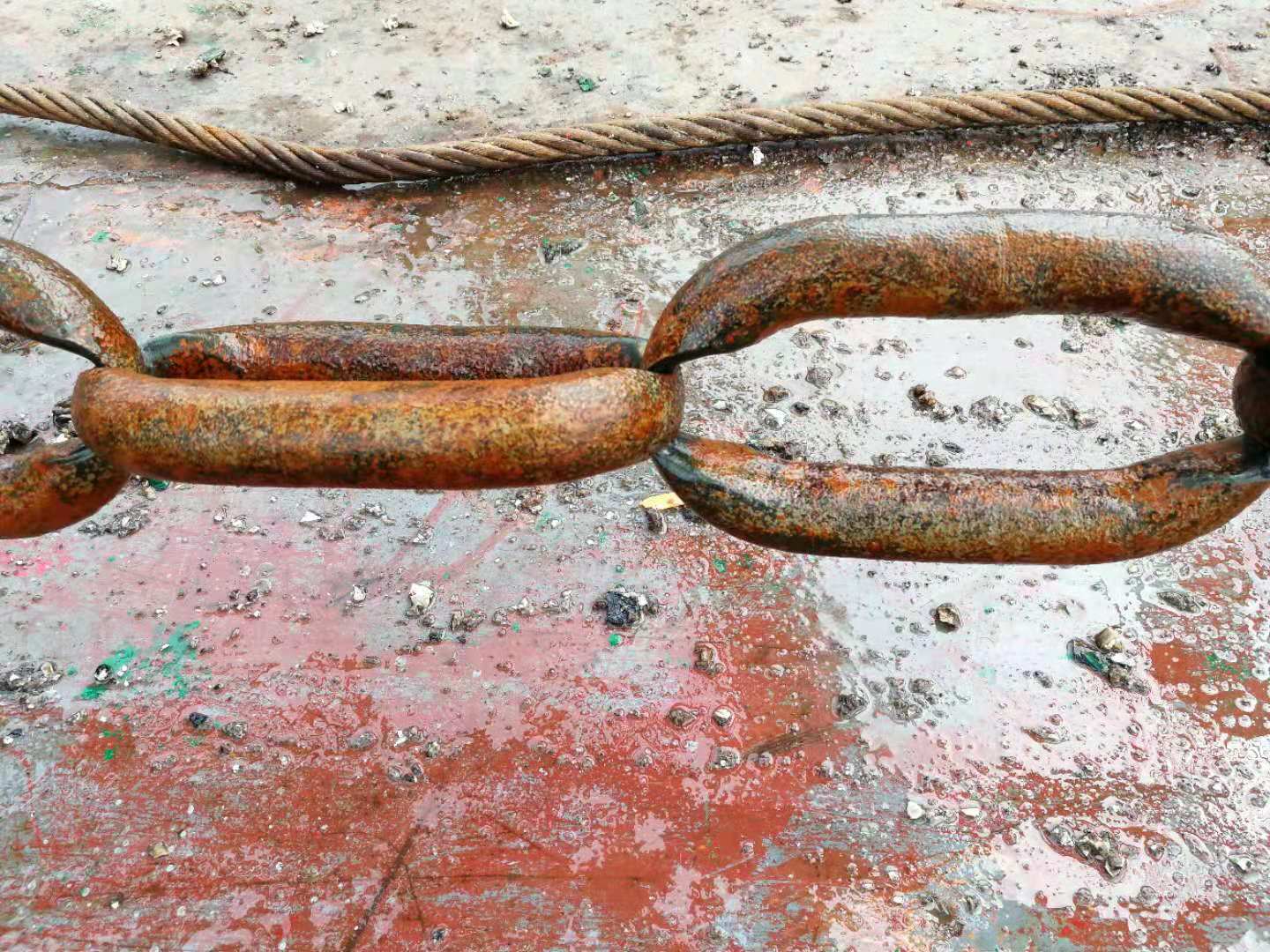

The weaknesses of traditional steel mooring/navigation buoys are that they are rusty and worn out and share the pulling forces among their cylindrical structures. In the case of ageing or collision, especially the Private Mooring Buoys, they may be creaked, holed, sunk, or even pulled apart during a heavy storm.

Non-metal Mooring Buoys (EVA-Polyurea and GRP-PU)

With the availability of new materials and high technology supports nowadays, we worked with manufacturers in mainland China (PRC) and established production lines to develop Non-metal Mooring Buoys that are either made in high-density Ethylene-Vinyl Acetate (EVA) assembled with an all-in-one stainless-steel Middle Shaft includes the top and bottom mooring rings, then thoroughly sprayed with 5–8 mm thick of Polyurea for watertight, maintenance-free and long-lasting; or used the Fiberglass (GRP) Through-Chain Module filled with rigid Polyurethane (PU) inside and fitted with the Reinforced Rubber Fender outside.

Polyurea is a newly developed material applied by spraying with a computerised system. It is a very high-abrasive, heat-resistant, maintenance-free and long-lasting fabric; it can be mixed with the desired colour and dried immediately upon spraying.

The design of the Non-metal Mooring Buoys is to remove the stress (pulling forces) from the cylindrical body of the Buoy; thus, all the pulling forces will be directly sustained by the Stainless-steel Middle Shaft or the Mooring Chain. The cylindrical body of the Buoy is either wholly made of EVA or a Fiberglass Module filled with rigid Polyurethane (PU) to ensure watertight and long-lasting; it only acts as a floatation unit to support the weight of the Mooring Chain and maintains 1/3 – 1/2 to stay afloat on the surface as required.

Despite the weight and size of an EVA-Polyurea Mooring Buoy being much less than a Steel Mooring Buoy under the exact buoyancy requirement, it is more long-lasting (10 years or more) and maintenance-free for long-term operation. In the case of collision, the soft, lightweight and highly abrasive EVA-Polyurea material will significantly reduce the impact forces and cause no damage to the Boat and the Buoy. Over some time, when marine barnacles are found on the surface and underneath an EVA-Polyurea Mooring Buoy, it (only weighs 1/4 of a Steel Buoy) can be easily flipped over 90 degrees on the surface and cleaned in place without removal and repainting. EVA-Polyurea Mooring Buoys overcame most of the previous problems on the Steel Mooring Buoys and waived the ongoing maintenance costs.

There are many Steel-fibreglass Through-Chain Buoys and HDPE Buoys available nowadays. The cylindrical body of these Steel-fibreglass or HDPE Mooring Buoys will indeed last better in seawater than a Steel Mooring Buoy; however, its hollow structure or the middle shaft made of mild-steel may pull apart from the cylindrical body due to rusty and worn out after a couple of years. Eventually, the heavy rust and marine barnacles generated inside the hollow structure will seize the Chain inside the Through-Chain Buoy. Besides the middle shaft or hollow structure problems, some HDPE Buoys are too narrow and too high; please note that the higher the Mooring Buoy afloat on the surface, the higher the chance of leaning sideways, causing the growth of marine barnacles on the top half of the Mooring Buoy. We only tailor-made all EVA-Polyurea Mooring Buoys based on the Customer’s Boat and Chain requirements.

EVA-Polyurea Mooring Buoys made by us are available in two versions: The Middle Shaft Version consists of a middle shaft together with the top and bottom mooring rings all-in-ones made of stainless steel and fully wrapped around by EVA, then thoroughly sprayed with 5–8 mm thick of Polyurea for watertight, maintenance-free and long-lasting; or the Through-Chain Version consists of a stainless-steel hollow structure that allows the Chain to go through. The colour choices of yellow, green, and red are available upon request.

Mooring Chains, Swivel and Shackles

A Mooring Chain connects the Mooring Buoy to the Concrete Sinker underwater, but most Boat Owners did not get what they paid for! The material composition of the Chain and the necessary components make a world difference in its pulling strength and durability, although they all look the same!

Mooring Chains (Stud-link, AM or Open-link, PM) are made of forged steel and are classified into Three Categories (Grade I, II and III). Grade I Chains are cheaper but erode much quicker in seawater conditions, and their pulling strength is 40 % less than the Grade II Chains. Grade II Chains are commonly used for Private Boat Moorings, while Grade III Chains are primarily utilised for Oceangoing Vessels.

The mooring area’s water depth primarily decides the required length of a Mooring Chain. Once the Chain Length is identified, a Mooring Chain (No matter whether Grade II or Grade III, Stud-link or Open-link) should be tailor-made at the Chain Factory by fitting an Enlarged end-link at both ends of the Chain, especially for the Stud-link Chain, to allow the proper connection with a standard Type-D Anchor Shackle (It is usually 40 % bigger than a typical Chain Link). A standard Swivel is preferably fitted on each Chain about one meter below the Mooring Buoy. After the whole length of the Mooring Chain with all required components is fitted, it will be load-tested according to the standard and coated with Black Asphalt Paint for delivery. Hot-dipped galvanised finishing that reduces marine barnacles in seawater conditions can be done at additional costs.

Boat Owners should not accept any Chains that are cut from the Contractor’s local stock, as such Chains have no Enlarged end-links at both ends, no standard Swivel fitted, and no load-testing has been done. These Chains, especially the Stud-link Chains, may only be connected with the undersized or inadequate Shackles! Thus, the entire Mooring System is downgraded and non-compliant!

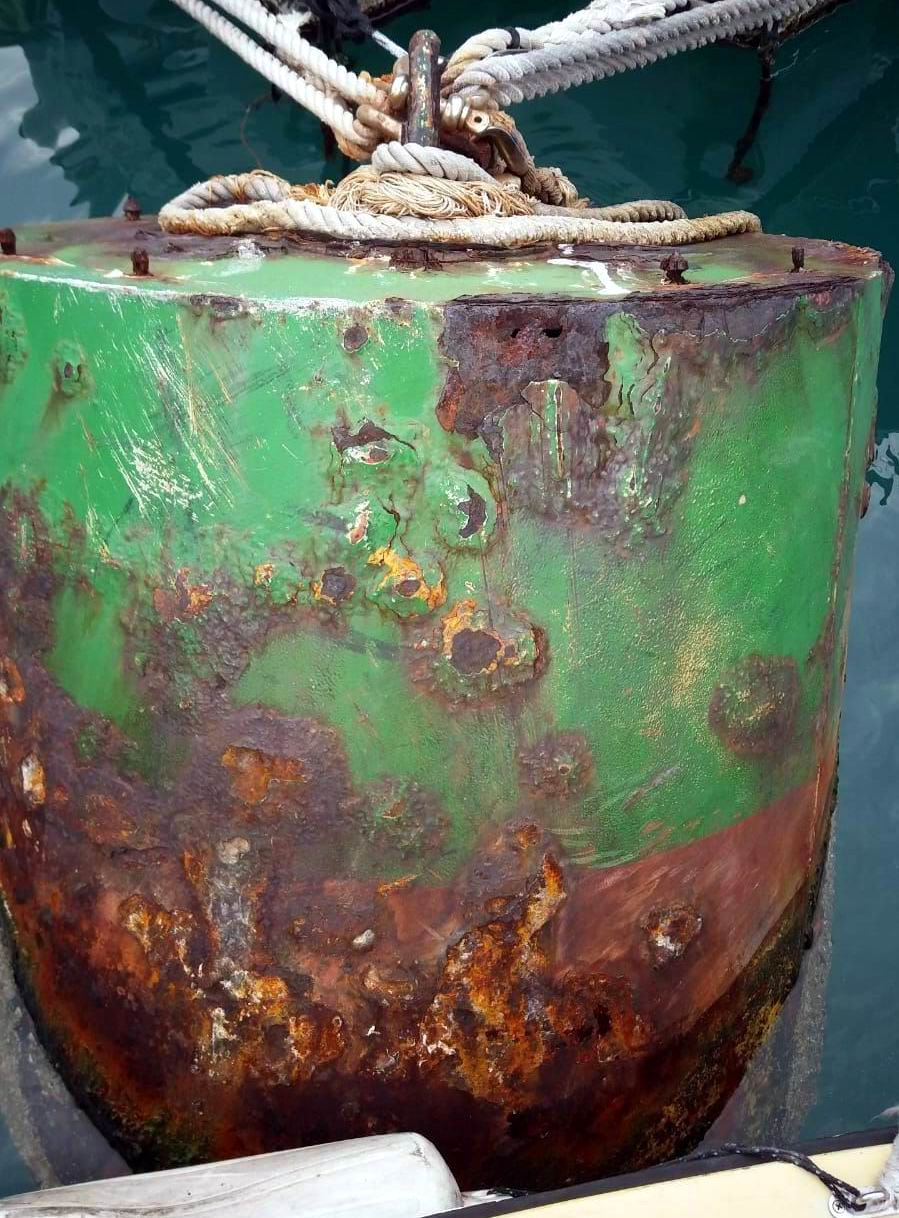

Concrete Sinkers

Unlike nowadays, most Concrete Sinkers laid before were underweight (did not meet the required weight) due to the lack of prior inspection by the Hong Kong Marine Department. A concrete sinker that meets the necessary weight (the cubic volume) seems simple for most Contractors; however, the Lifting Eye Ring is still and always undersized!

If the Lifting Eye Ring is made undersized (Ring diameter and radius are too small), the standard Type-D Anchor Shackle (40 % bigger than a typical Chain Link) can’t go through; thus, a non-standard or undersized Shackle will be used.

Moreover, after these undersized Eye Ring and Shackle submerged underwater for a couple of years, would they still sustain the Mooring Chain’s pulling forces during a heavy storm? Would they pull apart underwater during the subsequent lift for the next Chain renewal?

If it does happen, the Boat Owner must first pay to recover the existing Sinker that has a broken Lifting Eye Ring (Diving works required) and then pay again for a new Sinker and reinstallation!

Mooring Ropes

Finally, no matter how well a Mooring System has been made and installed, improperly secured or misusing an undersized Swivel on the Mooring Ropes may cause the Boat to be lost during a heavy storm. About ten Boats were lost after the Super Typhoon [Mangkhut] because the Stainless-steel Swivel on the Mooring Ropes failed.

Liability of the Mooring System

Boat Owners or Yacht Clubs do not always understand all the requirements of a Mooring System. Some Contractors are also unaware of the compliance standards of a Mooring System or choose to ignore them if the fulfilment cost is comparatively high, especially for those components under the water (no one will see).

Nevertheless, the Boat Owners are ultimately responsible for the quality and compliance of the entire Mooring System. In case of any failure during a heavy storm, when you proceed with the damage claims (your Boat and the implicated parties) to the Insurance Company, they will then employ an Expert or Ship Surveyor to inspect and verify the entire Mooring System for non-compliance. Thus, selecting a professional and experienced Contractor for the job in the first place is extremely important.

Our Quality Products and Services

Kinetic Key Company Limited (KKCL) has been a Professional Contractor in Marine Works, above and under the water, in Hong Kong and China (PRC) for over 35 years. KKCL established production lines in China (PRC) to design and tailor-made the EVA-Polyurea Mooring Buoys and HDPE or Steel Warning Buoys with Solar-powered Lantern (Class 1 & Class 2) upon Customers’ Boat or Project requirements, including the supply of all required Components, such as Mooring Chains with standard Swivel, Type-D Anchor Shackles and Concrete Sinkers etc. All products fully meet the requirements of the Hong Kong Marine Department.

As requested, KKCL has designed and supplied about 30 pieces of the EVA-Polyurea Wreck Buoys with Solar-powered Lanterns for the Hong Kong Marine Department.

Over 200 pieces of EVA-Polyurea Mooring Buoys have been provided and installed for Aberdeen Boat Club (ABC) and Private Boat Owners at different mooring areas since 2018, and no extensive care and maintenance has been required until now.

KKCL also provides underwater inspections and compliance surveys on Mooring Facilities for Boat Owners and Insurance Companies upon request.

If you want an EVA-Polyurea Mooring Buoy, a sample is available at our warehouse in the New Territories for your inspection and hands-on experience.

Mooring Systems

The weaknesses of traditional steel mooring/navigation buoys are that they are rusty and worn out and share the pulling forces among their cylindrical structures. In the case of ageing or collision, especially the Private Mooring Buoys, it may be creaked, holed, sunk, or even pulled apart during a heavy storm.

Non-metal Mooring Buoys (EVA-Polyurea and GRP-PU)

With the availability of new materials and high technology supports nowadays, we worked with manufacturers in mainland China (PRC) and established production lines to develop Non-metal Mooring Buoys that are either made in high-density Ethylene-Vinyl Acetate (EVA) assembled with an all-in-one stainless-steel Middle Shaft includes the top and bottom mooring rings, then thoroughly sprayed with 5–8 mm thick of Polyurea for watertight, maintenance-free and long-lasting; or used the Fiberglass (GRP) Through Chain Module filled with rigid Polyurethane (PU) inside and fitted with the Reinforced Rubber Fender outside.

Polyurea is a newly developed material applied by spraying with a computerised system. It is a very high-abrasive, heat-resistant, maintenance-free, and long-lasting fabric; it can be mixed with the desired colour and dried immediately upon spraying.

The design of the Non-metal Mooring Buoys is to remove the stress (pulling forces) from the cylindrical body of the Buoy; thus, all the pulling forces will be directly sustained by the Stainless-steel Middle Shaft or the Mooring Chain. The cylindrical body of the Buoy is either made of wholly EVA or a Fiberglass Module filled with rigid Polyurethane (PU) to ensure watertight and long-lasting; it only acts as a floatation unit to support the weight of the Mooring Chain and maintains 1/3 – 1/2 to stay afloat on the surface as required.

Despite the weight and size of an EVA-Polyurea Mooring Buoy being much less than a Steel Mooring Buoy under the exact buoyancy requirement, it is more long-lasting (10 years or more) and maintenance-free for long-term operation. In the case of collision, the soft, lightweight and highly abrasive EVA-Polyurea material will significantly reduce the impact forces and cause no damage to the Boat and the Buoy. Over some time, when marine barnacles are found on the surface and underneath an EVA-Polyurea Mooring Buoy, it (only weighs 1/4 of a Steel Buoy) can be easily flipped over 90 degrees on the surface and cleaned in place without removal and repainting. EVA-Polyurea Mooring Buoys overcame most of the previous problems on Steel Mooring Buoys and waived the ongoing maintenance costs.

There are many Steel-fibreglass Through-Chain Buoys and HDPE Buoys available nowadays. The cylindrical body of these Steel-fibreglass or HDPE Mooring Buoys will indeed last better in seawater than a Steel Buoy; however, its hollow structure or the middle shaft made of mild-steel may pull apart from the cylindrical body due to rusty and worn out after a couple of years. Eventually, the heavy rust and marine barnacles generated inside the hollow structure will seize the Chain inside the Through Chain Buoy. Besides the middle shaft and hollow structure problems, some HDPE Buoys are too narrow and too high; please note that the higher the Mooring Buoy afloat on the surface, the higher the chance of leaning sideways, causing the growth of marine barnacles on the top half of the Mooring Buoy. We only tailor-made all EVA-Polyurea Mooring Buoys based on the Customer’s Boat and Chain requirements.

EVA-Polyurea Mooring Buoys made by us are available in two versions: The Middle Shaft Version consists of a middle shaft together with the top and bottom mooring rings all-in-ones made of stainless steel and fully wrapped around by EVA, then thoroughly sprayed with 5–8 mm thick of Polyurea for watertight, maintenance-free and long-lasting; or the Through-Chain Version consists of a stainless-steel hollow structure that allows the Chain to go through. The colour choices of yellow, green, and red are available upon request.

Mooring Chains, Swivel and Shackles

A Mooring Chain connects the Mooring Buoy to the Concrete Sinker underwater, but most Boat Owners did not get what they paid for! The material composition of the Chain and the necessary components make a world difference in its pulling strength and durability, although they all look the same!

Mooring Chains (Stud-link, AM or Open-link, PM) are made of forged steel and are classified into Three Categories (Grade I, II and III). Grade I Chains are cheaper but erode much quicker in seawater conditions, and their pulling strength is 40 % less than the Grade II Chains. Grade II Chains are commonly used for Private Boat Mooring, while Grade III Chains are primarily utilised for Oceangoing Vessels.

The mooring area’s water depth primarily decides the required length of a Mooring Chain. Once the Chain Length is identified, a Mooring Chain (No matter whether Grade II or Grade III, Stud-link or Open-link) should be tailor-made at the Chain Factory by fitting an Enlarged end-link at both ends of the Chain, especially for the Stud-link Chain, to allow proper connection with a standard Type-D Anchor Shackle (It is usually 40 % bigger than a typical Chain Link). A standard Swivel is preferably fitted on each Chain about one meter below the Mooring Buoy. After the whole length of the Mooring Chain with all required components is fitted, it will be load-tested according to the standard and coated with Black Asphalt Paint for delivery. Hot-dipped galvanised finishing that reduces marine barnacles in seawater conditions can be done at additional costs.

Boat Owners should not accept any Chains that are cut from the Contractor’s local stock, as such Chains have no Enlarged end-links at both ends, no standard Swivel fitted, and no load-testing has been done. These Chains, especially the Stud-link Chains, may only be connected with the undersized or inadequate Shackles! Thus, the entire Mooring System is downgraded and non-compliant!

Concrete Sinkers

Unlike nowadays, most Concrete Sinkers laid before were underweight (did not meet the required weight) due to the lack of prior inspection by the Hong Kong Marine Department. A concrete sinker that meets the necessary weight (the cubic volume) seems simple for most Contractors; however, the Lifting Eye Ring is still and always undersized!

If the Lifting Eye Ring is made undersized (Ring diameter and radius are too small), the standard Type-D Anchor Shackle (40 % bigger than a typical Chain Link) can’t go through; thus, a non-standard or undersized Shackle will be used. Moreover, after these undersized Eye Ring and Shackle submerged underwater for a couple of years, would they still sustain the Mooring Chain’s pulling forces during a heavy storm? Would they pull apart underwater during the subsequent lift for the next Chain renewal?

If it does happen, the Boat Owner must first pay to recover the existing Sinker that has a broken Lifting Eye Ring (Diving works required) and then pay again for a new Sinker and reinstallation!

Mooring Ropes

Finally, no matter how well a Mooring System has been made and installed, improperly secured or misusing an undersized Swivel on the Mooring Ropes may cause the Boat to be lost during a heavy storm. About ten Boats were lost after the Super Typhoon [Mangkhut] because the Stainless-steel Swivel on the Mooring Ropes failed.

Liability of the Mooring System

Boat Owners or Yacht Clubs do not always understand all the requirements of a Mooring System. Some Contractors are also unaware of the compliance standards of a Mooring System or choose to ignore them if the fulfilment cost is comparatively high, especially for those components under the water (no one will see).

Nevertheless, the Boat Owners are ultimately responsible for the quality and compliance of the entire Mooring System. In case of any failure during a heavy storm, when you proceed with the damage claims (your Boat and the implicated parties) to the Insurance Company, they will then employ an Expert or Ship Surveyor to inspect and verify the entire Mooring System for non-compliance. Thus, selecting a professional and experienced Contractor for the job in the first place is extremely important.

Our Quality Products and Services

Kinetic Key Company Limited (KKCL) has been a Professional Contractor in Marine Works, above and under the water, in Hong Kong and China (PRC) for over 35 years. KKCL established production lines in China (PRC) to design and tailor-made the EVA-Polyurea Mooring Buoys and HDPE or Steel Warning Buoys with Solar-powered Lantern (Class 1 & Class 2) upon Customers’ Boat or Project requirements, including the supply of all required Components, such as Mooring Chains with standard Swivel, Type-D Anchor Shackles and Concrete Sinkers etc. All products fully meet the requirements of the Hong Kong Marine Department.

As requested, KKCL has designed and supplied about 30 pieces of the EVA-Polyurea Wreck Buoys with Solar-powered Lanterns for the Hong Kong Marine Department.

Over 200 pieces of EVA-Polyurea Mooring Buoys have been provided and installed for Aberdeen Boat Club (ABC) and Private Boat Owners at different mooring areas since 2018, and no extensive care and maintenance has been required until now.

KKCL also provides underwater inspections and compliance surveys on Mooring Facilities for Boat Owners and Insurance Companies upon request.

If you want an EVA-Polyurea Mooring Buoy, a sample is available at our warehouse in the New Territories for your inspection and hands-on experience.

EVA-Polyurea Mooring Buoys Vs Traditional Steel Mooring Buoys

Item |

Considerations |

EVA-Polyurea Mooring Buoys |

Traditional Steel Mooring Buoys |

|

1. |

Rusty and Worn Out |

EVA-Polyurea Mooring Buoys never rust or wear out. The top and bottom Mooring Rings and Middle Shaft are all-in-one and made of stainless steel; no painting or maintenance is required. | A Steel Mooring Buoy and its top and bottom Mooring Rings made of mild steel require continuous maintenance, including removal, repair, anti-fouling painting and replacement almost every two years. |

|

2. |

Pulling Forces |

Sustaining all pulling forces by the Middle Shaft. The Mooring Buoy itself only acts as a floatation unit to support the weight of the Mooring Chain. | Sharing the pulling forces among the cylindrical structure of the Mooring Buoy. In case of ageing or lack of maintenance, it may be creaked, holed, sunk or pulled apart during a heavy storm. |

|

3. |

Collision |

The cylindrical body of an EVA-Polyurea Mooring Buoy is a soft, lightweight and highly abrasive material. In a collision, the impact forces will significantly reduce, causing no damage to the Boat and the Buoy. |

Damages to the Boat and Mooring Buoy, even in a minor collision. |

|

4. |

Weight |

An EVA-Polyurea Mooring Buoy of 1.0 meters in diameter only weighs about 120 kg. The Mooring Buoy’s material (EVA) is lightweight (buoyant), long-lasting and maintenance-free. | A Steel Mooring Buoy of 1.0 meters in diameter weighs about 550 kg. If it is ageing or damaged (cracked and holed), it will sink unless filled with Styrofoam. However, this will require additional costs and procedures. |

|

5. |

Buoyancy |

The weight of a Mooring Chain 26 mm x 12 meters in length is about 170 kg (downward force). To maintain 1/3 – 1/2 of the Mooring Buoy stays afloat on the surface as required, an EVA-Polyurea Mooring Buoy of 0.8 meters in diameter only needs 0.8 meters height to offset the downward forces and maintain about 0.4 meters stay afloat on the surface. | To ensure that 1/3 – 1/2 of the Mooring Buoy stays afloat on the surface as required, a Steel Mooring Buoy of 1.0 meters in diameter needs about 1.2 meters height to offset the downward forces and maintain about 0.6 meters stay afloat on the surface. The higher the Mooring Buoy floats on the surface, the higher the chance of leaning sideways, causing the marine barnacles to grow and wear out the Buoy’s top half. |

|

6. |

Maintenance and Durability |

An EVA-Polyurea Mooring Buoy is very lightweight (Only weighs about 1/4 of a Steel Buoy); over some time, when marine barnacles are found on the surface and underneath the Mooring Buoy, it can be easily flipped over 90 degrees on the surface and cleaned in place without removal and repainting.

EVA-Polyurea Mooring Buoy is long-lasting and maintenance-free; it may last about ten years under normal usage without extensive care. |

Over some time, when rusty and marine barnacles are found on the surface and underneath a Steel Mooring Buoy, additional costs are required for removal, cleaning, repairing, repainting, and replacement. A Steel Mooring Buoy may only last about five years, even under reasonable good maintenance. |

EVA-Polyurea Buoys Vs Traditional Steel Buoys

| Item | Concerns | EVA-Polyurea Buoys | Steel Buoys |

|

1. |

Rusty and Worn Out |

EVA-Polyurea Mooring Buoys never rust or wear out. The top and bottom Mooring Rings and Middle Shaft are all-in-one and made of stainless steel; no painting or maintenance is required. | A Steel Mooring Buoy and its top and bottom Mooring Rings made of mild steel require continuous maintenance, including removal, repair, anti-fouling painting and replacement almost every two years. |

|

2. |

Pulling Forces |

Sustaining all the pulling forces by the Middle Shaft. The Mooring Buoy itself only acts as a floatation unit to support the weight of the Mooring Chain. | Sharing the pulling forces among the cylindrical structure of the Buoy. In case of ageing or lack of maintenance, it may be creaked, holed, sunk or pulled apart during a heavy storm. |

|

3. |

Collision |

The cylindrical body of an EVA-Polyurea Mooring Buoy is a soft, lightweight and highly abrasive material. In a collision, the impact forces will significantly reduce, causing no damage to the Boat and the Buoy. |

Damages to the Boat and Mooring Buoy, even in a minor collision. |

|

4. |

Weight |

An EVA-Polyurea Mooring Buoy of 1.0 meters in diameter only weighs about 120 kg. The Mooring Buoy’s material (EVA) is lightweight (buoyant), long-lasting and maintenance-free. | A Steel Mooring Buoy of 1.0 meters in diameter weighs about 550 kg. If it is ageing or damaged (cracked and holed), it will sink unless filled with Styrofoam. However, this will require additional costs and procedures. |

|

5. |

Buoyancy |

The weight of a Mooring Chain 26 mm x 12 meters in length is about 170 kg (downward force). To maintain 1/3 – 1/2 of the Mooring Buoy stays afloat on the surface as required, an EVA-Polyurea Mooring Buoy of 0.8 meters in diameter only needs 0.8 meters height to offset the downward forces and maintain about 0.4 meters stay afloat on the surface. | To ensure 1/3 – 1/2 of the Mooring Buoy stays afloat on the surface as required, a Steel Mooring Buoy of 1.0 meters in diameter needs about 1.2 meters height to offset the downward forces and maintain about 0.6 meters stay afloat on the surface. The higher the Mooring Buoy floats on the surface, the higher the chance of leaning sideways, causing the marine barnacles to grow and wear out the Buoy’s top half. |

|

6. |

Maintenance and Durability |

An EVA-Polyurea Mooring Buoy is very lightweight (Only weighs about 1/4 of a Steel Buoy); over some time, when marine barnacles are found on the surface and underneath the Mooring Buoy, it can be easily flipped over 90 degrees on the surface and cleaned in place without removal and repainting.

An EVA-Polyurea Mooring Buoy is long-lasting and maintenance-free; it may last about ten years under normal usage without extensive care. |

Over some time, when rusty and marine barnacles are found on the surface and underneath a Steel Mooring Buoy, additional costs are required for removal, cleaning, repairing, repainting, and replacement. A Steel Mooring Buoy may only last about five years, even under reasonable good maintenance. |

Manufacturing of the Non-metal Mooring Buoys and Solar-powered EVA Wreck Buoys

All Non-metal Mooring Buoys and Solar-powered Warning Buoys (Class 1 and Class 2) are tailor-made at our production lines in mainland China (PRC) to meet the Customers’ Boat and Project requirements. All products fully meet the requirements of the Hong Kong Marine Department.

As requested, KKCL has designed and supplied about 30 pieces of the EVA-Polyurea Wreck Buoys with Solar-powered lanterns for the Hong Kong Marine Department.

The manufacturing processes of the EVA-Polyurea Middle Shaft Mooring Buoys, Marine Solar-powered EVA Wreck Buoys and GRP-PU Through-Chain Mooring Buoys are as follows:

| 1. | Firstly, assemble the Pre-cast EVA with the all-in-one stainless steel middle shaft to form the size of the required EVA Buoy. Build up the Fiberglass (GRP) Module with the stainless steel hollow structure to form the size of the required GRP Buoy. |

| 2. | Secondly, the computerised system is used to spray the EVA cylindrical body with several coats (5–8 mm thick) of Polyurea mixed with the desired colour. Polyurea is a newly developed material that is highly abrasive, heat resistant and never worn out. It will dry immediately upon spraying.

For Fiberglass (GRP) Through-Chain Buoys, install the Reinforced Rubber Fenders, then fill the GRP Module with rigid Polyurethane (PU). Each Through-Chain Buoy will have a separate stainless steel Mooring Ring for proper chain connection and boat mooring. |

| 3. | Finally, dress up, mark the assigned Buoy Number as required, complete the anti-fouling painting, and pack up for delivery. |

Buoys Production

All Non-metal Mooring Buoys and Solar-powered Warning Buoys (Class 1 and Class 2) are tailor-made at our production lines in mainland China (PRC) to meet the Customers’ Boat and Project requirements. All products fully meet the requirements of the Hong Kong Marine Department.

As requested, KKCL has designed and supplied about 30 pieces of the EVA-Polyurea Wreck Buoys with Solar-powered lanterns for the Hong Kong Marine Department.

The manufacturing processes of the EVA-Polyurea Middle Shaft Mooring Buoys, Marine Solar-powered EVA Wreck Buoys and GRP-PU Through-Chain Mooring Buoys are as follows:

| 1. | Firstly, assemble the Pre-cast EVA with the all-in-one stainless steel middle shaft to form the size of the required EVA Buoy. Build up the Fiberglass (GRP) Module with the stainless steel hollow structure to form the size of the required GRP Buoy. |

| 2. | Secondly, the computerised system is used to spray the EVA cylindrical body with several coats (5–8 mm thick) of Polyurea mixed with the desired colour. Polyurea is a newly developed material that is highly abrasive, heat resistant and never worn out. It will dry immediately upon spraying.

For Fiberglass (GRP) Through-Chain Buoys, install the Reinforced Rubber Fenders, then fill the GRP Module with rigid Polyurethane (PU). Each Through-Chain Buoy will have a separate stainless steel Mooring Ring for proper chain connection and boat mooring. |

| 3. | Finally, dress up, mark the assigned Buoy Number as required, complete the anti-fouling painting, and pack up for delivery. |

Boat Mooring Requirements in Hong Kong

The size of a Mooring System depends on the Boat’s total length. The Mooring Chain’s size and the Concrete Sinker’s weight required will be specified in the Letter of Permission from the Hong Kong Marine Department. The type and the size of the Mooring Buoy are not listed; however, the Mooring Buoy is required to have sufficient buoyancy to support the weight of the Chain at the fullest stretch and should be 33 – 50 % greater than the combined weight of the suspended components (i.e. 1/3 – 1/2 of the Buoy should stay afloat on the surface after it has been chained up).

Generally, a Boat’s total length between 5 – 8 meters will use a Chain size of 12 – 18 mm and an EVA Mooring Buoy of 0.6 meters in diameter will be used; a Boat’s total length between 9 – 11 meters will use a Chain size of 25 – 32 mm, and an EVA Buoy of 0.7 – 0.8 meter in diameter will be required. A Boat’s total length between 11 – 26 meters will use a Chain size of 32 – 40 mm, and an EVA Buoy of 1.0 meters in diameter will be required; a Boat’s total length between 24 – 41 meters will use a Chain size of 40 – 45 mm, and an EVA Buoy of 1.1 – 1.2 meters in diameter will be required. A Boat’s total length of 42 – 56 meters will use a Chain size of 50 mm, and an EVA Buoy of 1.3 meters in diameter (dependent upon the water depth and Chain Length) will be required.

Please note that the Buoys’ Diameter mentioned above will be much bigger and heavier if the Steel Mooring Buoys are used.

EVA-Polyurea Mooring Buoys and HDPE or Steel Warning Buoys with Solar-powered Lantern

Our EVA-Polyurea Mooring Buoys, made with a stainless steel Middle Shaft, are very lightweight (buoyant), soft, highly abrasive, and never worn out. It may last about ten years without extensive care. With our fully equipped production lines in mainland China (PRC), the cost of making an EVA-Polyurea Buoy is comparable to a steel mooring Buoy with Styrofoam inside and Fibreglass outside, but the durability and maintenance-free are much better.

Kinetic Key Company Limited (KKCL) is more than capable of supplying and installing the full range of Mooring Facilities (Mooring Buoys, Mooring Chains and Concrete Sinkers) and High-Density Polyethylene (HDPE) or Steel Warning Buoys with Solar-powered Lantern (Class 1 & Class 2) for Yacht Clubs, Private Boat Owners and Marine Construction Companies. All products fully meet the requirements of the Hong Kong Marine Department.

If you want an EVA-Polyurea Mooring Buoy, a sample is available at our warehouse in the New Territories for your inspection and hands-on experience.

Commercial Diving Services

KKCL is currently an Exclusive Diving Contractor of the Hong Kong Government Dockyard, responsible for providing emergency underwater services to over 200 Government Vessels patrolling the Hong Kong water.

Underwater services on mooring facilities, wreck recovery and marine maintenance for Yacht Clubs, Private Boat Owners and Marine Construction Companies are available upon request. For more information about Commercial Diving Services, please browse [Commercial Diving].

Boat Mooring Requirements in Hong Kong

The size of a Mooring System depends on the Boat’s total length. The Mooring Chain’s size and the Concrete Sinker’s weight required will be specified in the Letter of Permission from the Hong Kong Marine Department. The size and the type of Mooring Buoy are not listed; however, the Mooring Buoy is required to have sufficient buoyancy to support the weight of the Chain at the fullest stretch and should be 33 – 50 % greater than the combined weight of the suspended components (i.e. 1/3 – 1/2 of the Buoy should stay afloat on the surface after it has been chained up).

Generally, a Boat’s total length between 5 – 8 meters will use a Chain size of 12 – 18 mm and an EVA Mooring Buoy of 0.6 meters in diameter will be used; a Boat’s total length between 9 – 11 meters will use a Chain size of 25 – 32 mm, and an EVA Buoy of 0.7 – 0.8 meter in diameter will be required. A Boat’s total length between 11 – 26 meters will use a Chain size of 32 – 40 mm, and an EVA Buoy of 1.0 meters in diameter will be required; a Boat’s total length between 24 – 41 meters will use a Chain size of 40 – 45 mm, and an EVA Buoy of 1.1 – 1.2 meters in diameter will be used. A Boat’s total length of 42 – 56 meters will use a Chain size of 50 mm, and an EVA Buoy of 1.3 meters in diameter (dependent upon the water depth and Chain Length) will be required.

Please note that the Buoys’ Diameter mentioned above will be much bigger and heavier if the Steel Mooring Buoys are used.

EVA-Polyurea Mooring Buoys and HDPE or Steel Warning Buoys with Solar-powered Lantern

Our EVA-Polyurea Mooring Buoys, made with a stainless steel Middle Shaft, are very lightweight (buoyant), soft, highly abrasive, and never worn out. It may last about ten years without extensive care. With our fully equipped production lines in mainland China (PRC), the cost of making an EVA-Polyurea Buoy is comparable to a steel mooring Buoy with Styrofoam inside and Fibreglass outside, but the durability and maintenance-free are much better.

Kinetic Key Company Limited (KKCL) is more than capable of supplying and installing the full range of Mooring Facilities (Mooring Buoys, Mooring Chains and Concrete Sinkers) and High-Density Polyethylene (HDPE) or Steel Warning Buoys with Solar-powered Lantern (Class 1 & Class 2) for Yacht Clubs, Private Boat Owners and Marine Construction Companies. All products fully meet the requirements of the Hong Kong Marine Department.

If you want an EVA-Polyurea Mooring Buoy, a sample is available at our warehouse in the New Territories for your inspection and hands-on experience.

Commercial Diving Services

KKCL is currently an Exclusive Diving Contractor of the Hong Kong Government Dockyard, responsible for providing emergency underwater services to over 200 Government Vessels patrolling the Hong Kong water.

Underwater services on mooring facilities, wreck recovery and marine maintenance for Yacht Clubs, Private Boat Owners and Marine Construction Companies are available upon request. For more information about Commercial Diving Services, please browse [Commercial Diving].

For inquiries, please contact Mr Li at Tel. (852) 9488 4148 or (86) 138 2522 3300, WhatsApp 6952 8400 or E-mail kkli@kkcl.com.hk. We are confident that our Professional Teams will provide the best solutions for your inquiries.